Introduction: Redefining Progress in the 21st Century

As the world faces mounting environmental challenges—from resource depletion to mounting waste—societies are increasingly recognizing that the traditional linear model of “take, make, dispose” is unsustainable. The concept of Circular Technologies, rooted in the circular economy framework, has emerged as a blueprint for a sustainable industrial revolution. Unlike linear systems, circular technologies emphasize reduction, reuse, recycling, and regeneration, closing material loops and minimizing ecological footprints.

This transformation is not only about waste management but about reimagining entire production and consumption systems. Through advances in digital technology, artificial intelligence, materials science, and renewable energy, industries are engineering circular solutions that combine efficiency with sustainability.

1. The Philosophy Behind Circular Technologies

1.1 From Linear to Circular Thinking

The 20th century celebrated speed, mass production, and growth. However, this model was built on the assumption of infinite resources. Circular technologies challenge this notion, replacing it with systems that mimic nature’s cycles—where waste from one process becomes input for another.

This mindset shift requires not only innovation but also systemic collaboration among governments, corporations, and consumers. Circular technologies thus act as both an ideological and operational bridge between sustainability and industry.

1.2 The Role of Digitalization

Digitalization is the nervous system of circular innovation. Technologies like the Internet of Things (IoT), blockchain, and artificial intelligence (AI) enable traceability, predictive maintenance, and optimization of resource flows. These tools empower industries to measure, monitor, and minimize waste throughout a product’s lifecycle.

For instance, blockchain ensures transparency in recycled material sourcing, while IoT sensors in manufacturing lines detect inefficiencies and reduce energy use in real time.

2. Circular Manufacturing and Smart Materials

2.1 Designing Out Waste

Circular manufacturing begins with design philosophy. Engineers and designers now use eco-design principles, ensuring that products are modular, repairable, and recyclable. Software tools powered by AI simulate product lifecycles and predict potential waste points long before physical production begins.

Examples include companies like Philips developing lighting-as-a-service, where consumers pay for illumination rather than owning bulbs. This model incentivizes the company to build longer-lasting, efficient products that can be reassembled or reused.

2.2 Advanced Materials and Bio-innovation

Biotechnology is becoming a crucial ally. Bio-based plastics, lab-grown materials, and self-healing composites offer alternatives to resource-heavy materials. Innovations such as mycelium-based packaging or biodegradable polymers are redefining sustainability in design and manufacturing.

Furthermore, advances in nanotechnology have produced smart materials capable of changing properties based on temperature or use conditions, enabling longer product lifespans and reducing the need for replacements.

3. Urban Circular Systems: Smart Cities for a Sustainable Age

3.1 Circular Infrastructure

Cities are the engines of consumption and waste—but they are also the testing grounds for circular systems. Smart cities are integrating waste-to-energy systems, greywater recycling, and localized renewable microgrids to create closed-loop ecosystems.

For instance, in Amsterdam, construction waste is repurposed through 3D printing to create modular housing components, while digital twins of buildings track energy and material performance throughout their lifecycles.

3.2 Transportation and Shared Mobility

The mobility sector offers fertile ground for circular innovation. The rise of electric vehicle (EV) batteries recycling, autonomous car-sharing platforms, and urban logistics optimization algorithms contributes to reducing the environmental load of transportation.

Moreover, battery second-life applications—where used EV batteries power residential grids—demonstrate the power of circular thinking in extending resource utility beyond a single use.

4. Circular Data and Artificial Intelligence

4.1 AI for Circular Resource Management

Artificial intelligence is revolutionizing resource management by predicting waste patterns, optimizing recycling logistics, and supporting industrial symbiosis—the exchange of materials and energy between companies.

Machine learning models identify where materials can be repurposed, or where production lines can improve efficiency by mimicking natural cycles. For instance, Google’s AI for sustainability projects have reduced energy use in data centers by up to 40%.

4.2 Digital Twins and Lifecycle Optimization

Digital twins—virtual replicas of physical systems—allow industries to test sustainability scenarios before implementation. Through simulation, companies can predict environmental impacts, reduce waste, and maximize circular value.

By integrating AI and data analytics, digital twins extend beyond factories into urban infrastructure, transportation networks, and even agriculture, transforming how we perceive system efficiency.

5. Circular Economy in the Energy Sector

5.1 Renewable Energy and Storage Circularity

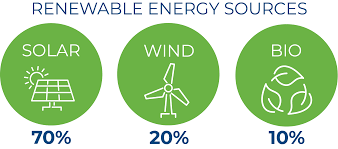

The transition to renewables must also embrace circular design. Solar panels, wind turbines, and batteries require rare minerals, creating potential new waste streams. Circular technologies help recover and reuse materials like lithium, cobalt, and silicon from decommissioned installations.

5.2 Hydrogen and Bioenergy Systems

Hydrogen and bioenergy technologies represent another frontier. By using waste biomass or industrial byproducts as feedstock, they generate clean energy while minimizing carbon output. Circular hydrogen ecosystems, in particular, integrate electrolysis powered by renewables and fuel cell recycling, forming a near-closed energy loop.

6. Business Transformation and New Value Models

6.1 From Ownership to Access

Circular technologies are reshaping business logic. The “Product-as-a-Service” model replaces ownership with access—consumers subscribe to services instead of buying goods. This creates a feedback loop between manufacturers and users, incentivizing long-lasting design.

6.2 Financial and Policy Incentives

Governments and financial institutions are recognizing circularity as a driver of innovation and resilience. Green bonds, carbon credits, and extended producer responsibility (EPR) schemes encourage companies to integrate circular design principles.

Meanwhile, investors increasingly favor ESG-aligned enterprises, pushing global corporations toward transparent and sustainable practices.

7. Challenges and the Path Forward

Despite the progress, circular technologies face obstacles—fragmented supply chains, high transition costs, and regulatory inertia. Technological innovation must be coupled with behavioral and systemic change.

Education, cross-sector partnerships, and open innovation platforms will be vital in accelerating circular transformation. The future of the circular economy depends not on isolated technologies but on their integration into cohesive, adaptive ecosystems.

Conclusion: Engineering Tomorrow’s Regenerative World

Circular technologies represent more than a set of tools—they embody a paradigm shift in how humanity interacts with resources. By merging sustainability with digital intelligence, biotechnology, and advanced manufacturing, circular systems can decouple economic growth from environmental degradation.

In the coming decades, success will not be measured solely by GDP, but by regenerative capacity—our ability to create systems that restore, renew, and sustain. As industries, governments, and citizens align under this vision, the age of waste may finally give way to an era of infinite renewal—a world built not on extraction, but on continuous, circular creation.