Introduction: When Sustainability Meets Digitalization

The 21st century marks a crossroads for global industry. Traditional production models—linear, extractive, and wasteful—are no longer viable in an era of resource scarcity and climate urgency. Meanwhile, digital technologies such as artificial intelligence, blockchain, and the Internet of Things (IoT) have unlocked unprecedented potential to reshape industrial ecosystems.

The intersection of these forces has given rise to a new paradigm: the digital circular economy. In this system, circular principles—reduce, reuse, recycle—are not merely aspirational ideals but data-driven realities, enforced and optimized through intelligent technologies.

This article explores how digital transformation is enabling circularity across industries, how companies are reinventing their value chains, and how global policy frameworks are fostering this evolution toward a sustainable industrial future.

1. The Rise of the Digital Circular Economy

1.1 From Industry 4.0 to Circular Industry 5.0

The Fourth Industrial Revolution brought automation, connectivity, and data-driven optimization. The emerging Industry 5.0, however, goes beyond efficiency—it aims for resilience, sustainability, and human-centric innovation.

In the circular context, Industry 5.0 leverages data analytics, machine learning, and robotics to close resource loops. Smart sensors track material flows in real-time, AI algorithms predict waste generation, and digital twins simulate recycling systems before implementation.

This convergence transforms production from a linear chain into a dynamic loop, where materials circulate, products are designed for reuse, and digital systems continuously learn to minimize waste.

1.2 Why Digitalization Matters for Circularity

Without data, circularity remains theoretical. Digital tools give visibility into where resources come from, how they are used, and where they go. Blockchain ensures trust and traceability; IoT enables continuous monitoring; and AI extracts actionable insights from vast industrial data.

For example, in a circular supply chain, companies can track components through blockchain-based ledgers, ensuring that every recycled material meets environmental standards and ethical sourcing criteria.

2. Smart Manufacturing and Predictive Circularity

2.1 Intelligent Design for Longevity

Digital design tools allow engineers to simulate product life cycles long before production. Through computer-aided design (CAD) integrated with AI, manufacturers can test durability, recyclability, and modularity virtually, identifying the most sustainable configurations.

Take Siemens’ digital factory model, which integrates sensors, simulation, and lifecycle analytics. Products are optimized not just for performance but for repairability and reusability, reducing material waste by up to 30%.

2.2 Predictive Maintenance and Resource Efficiency

IoT-enabled machinery can self-report wear and tear, enabling predictive maintenance that prevents unnecessary replacements. This extends product lifespans and minimizes downtime—key aspects of circular production.

In the automotive sector, predictive analytics is already saving tons of raw materials by optimizing parts replacement schedules, ensuring components are used to their full potential before being recycled or refurbished.

3. Blockchain and the New Age of Circular Trust

3.1 Transparency in the Supply Chain

Circular systems depend on trust—knowing that recycled materials are genuine, ethically sourced, and of high quality. Blockchain provides a decentralized ledger that verifies transactions and product origins.

For example, the Circularise platform uses blockchain to trace plastics across complex supply chains, ensuring that every actor—from polymer producers to recyclers—contributes to an auditable circular chain of custody.

3.2 Material Passports and Lifecycle Data

The concept of a “material passport”—a digital record of a product’s components and materials—enables recycling and remanufacturing. When a building or product reaches the end of its life, recyclers can access its passport to recover resources efficiently.

In Europe, the Madaster Platform already implements such digital passports for construction materials, transforming demolition waste into valuable input for new building projects.

4. Case Studies: Circular Innovation in Action

4.1 Ellen MacArthur Foundation and Global Leadership

The Ellen MacArthur Foundation has become a leading force in promoting digital circular models. Through partnerships with Google, Unilever, and Apple, the foundation advocates for data-driven redesign of product lifecycles.

Google’s AI for Circular Economy initiative uses machine learning to optimize data center cooling, reduce material waste, and track supply chain emissions in real time—saving both energy and resources.

4.2 Circular Manufacturing in Asia

Asian economies—particularly China, Japan, and South Korea—are pioneering industrial symbiosis zones. In these systems, waste from one factory becomes raw material for another, facilitated by shared digital platforms.

In China’s Suzhou Industrial Park, AI and big data analytics match supply and waste streams among hundreds of companies, creating a networked ecosystem where byproducts are revalorized into new inputs.

4.3 Circular Fashion and Digital Traceability

Fashion is one of the world’s most wasteful industries. Brands like H&M and Patagonia now deploy RFID tags and blockchain verification to track garment lifecycles—from cotton sourcing to resale and recycling.

Digital ID systems also allow consumers to scan QR codes to view a product’s sustainability score, empowering them to make informed, eco-friendly choices.

5. Artificial Intelligence and the Next Circular Leap

5.1 Data as the New Raw Material

AI’s ability to process massive datasets enables companies to uncover inefficiencies invisible to the human eye. By predicting demand, optimizing logistics, and detecting product degradation, AI ensures materials stay in circulation longer.

For instance, IBM’s AI-powered Material Recovery System analyzes recycling streams to identify valuable components, significantly improving recovery rates in electronic waste processing.

5.2 Autonomous Decision Systems

Future circular factories will use autonomous AI systems that make resource decisions in real time—adjusting production lines, redirecting waste, and prioritizing renewable energy use automatically. These self-learning systems create adaptive, regenerative industrial environments that respond dynamically to environmental and market signals.

6. Policy and Governance: Building the Digital Circular Framework

6.1 Global Policy Shifts

Governments are embedding circularity into digital transition strategies. The European Green Deal, for example, mandates circular product design and digital tracking systems for materials across industries.

Meanwhile, the United Nations’ Digital for Circular Economy Initiative (D4CE) fosters cross-border collaboration between policymakers, corporations, and researchers to harmonize standards and promote open innovation.

6.2 Incentivizing Circular Innovation

Financial and regulatory mechanisms—like carbon pricing, circular tax credits, and green procurement—are crucial for adoption. For instance, Japan’s Circular Economy Roadmap 2030 offers subsidies to companies that digitize recycling processes or adopt traceable materials databases.

7. Social and Economic Impacts

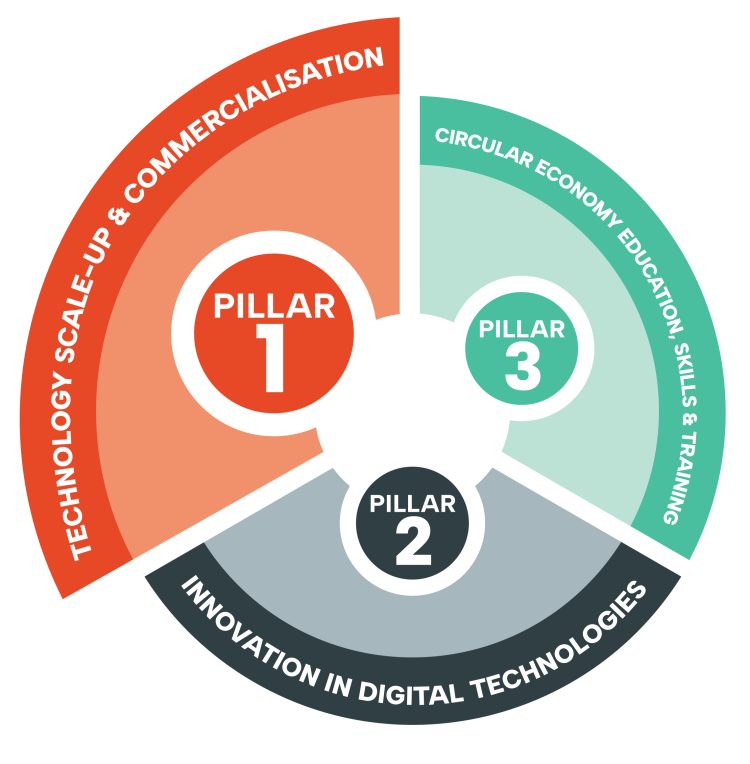

7.1 Circular Jobs and Digital Skills

The transition toward digital circularity will create new professions: data-driven sustainability analysts, circular designers, blockchain material auditors, and AI waste management engineers.

Education systems must evolve to equip workers with hybrid technical and ecological literacy, bridging the gap between coding and climate consciousness.

7.2 Equitable Transition and Global Inclusion

To ensure fairness, the circular digital economy must include developing regions. Technologies such as low-cost IoT devices and open-source blockchain protocols can empower small producers to participate in global circular markets.

Organizations like the World Bank’s Global Platform for Circular Economy support such inclusivity by funding digital infrastructure for waste management in emerging economies.

8. Challenges on the Road to Circular Digitalization

Despite rapid progress, barriers persist. Data interoperability, cybersecurity, and regulatory fragmentation threaten to slow adoption. Many industries still operate in silos, lacking the data-sharing culture necessary for full circular transparency.

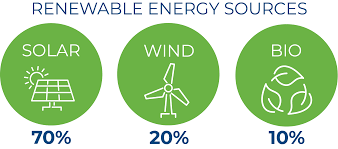

Additionally, digital systems consume energy—raising the paradox of digital carbon footprints. Thus, balancing the efficiency of AI and IoT with renewable energy integration is essential for net-positive outcomes.

9. The Vision Ahead: A Regenerative Industrial Civilization

As circular technologies and digital systems converge, humanity stands at the threshold of a regenerative industrial civilization. This vision transcends recycling—it redefines the meaning of progress itself.

In this future, factories are self-regulating ecosystems, supply chains are transparent and ethical, and products are born with the knowledge of how they will be reborn. Circularity becomes not a policy or trend, but the default logic of a sustainable economy.

Conclusion: Data, Design, and Destiny

Digital transformation has provided the missing link in humanity’s quest for circularity. Through intelligent design, blockchain trust, and AI optimization, industries can finally close material loops once thought impossible.

The challenge now is not technological but cultural—whether societies will embrace the shift from ownership to stewardship, from extraction to regeneration.

The promise of circular technology lies in using intelligence—both human and artificial—to restore balance between economy and ecology. In this balance lies the true foundation of sustainable prosperity.