Introduction

In the modern era, semiconductors form the backbone of almost every electronic device that powers daily life. From smartphones and laptops to data centers and advanced medical devices, semiconductors are the silent workhorses that enable computation, communication, and control. At its core, a semiconductor is a material whose electrical conductivity lies between that of a conductor and an insulator, allowing precise control of electric currents. This seemingly simple property, however, underpins an extraordinarily complex and multidisciplinary field that spans physics, chemistry, materials science, and electrical engineering.

This article aims to provide a comprehensive understanding of the science and engineering behind modern semiconductors. We will explore the physics of semiconductor materials, delve into device structures such as transistors and integrated circuits, examine fabrication processes, and discuss the challenges and innovations shaping the field today. By the end, readers will gain both conceptual and practical insights into how semiconductors are designed, manufactured, and optimized for increasingly complex applications.

1. Fundamental Principles of Semiconductors

1.1 Electrical Conductivity

Semiconductors are unique in their electrical behavior because their conductivity can be altered by introducing impurities (doping) or by applying external electric fields, light, or heat. At absolute zero, a pure semiconductor behaves as an insulator, with electrons tightly bound in the valence band. As temperature rises, electrons gain enough energy to jump across the energy gap (bandgap) into the conduction band, allowing current to flow.

- Intrinsic Semiconductors: Pure semiconductors like silicon (Si) or germanium (Ge) without significant impurities. Conductivity arises solely from thermally excited electrons and holes.

- Extrinsic Semiconductors: Doped semiconductors, where small amounts of atoms such as phosphorus or boron are introduced to increase electron (n-type) or hole (p-type) concentration.

This controllable conductivity is the basis for devices like diodes and transistors, which act as switches, amplifiers, or logic gates in circuits.

1.2 Energy Bands and Bandgap

Semiconductors are characterized by their bandgap energy (Eg), which determines the energy required for an electron to move from the valence band to the conduction band. Silicon, for example, has an Eg of ~1.12 eV at room temperature, while gallium arsenide (GaAs) has ~1.42 eV. The bandgap not only dictates electrical behavior but also affects optical properties, making some semiconductors suitable for LEDs or solar cells.

- Direct vs. Indirect Bandgap:

- Direct bandgap materials (e.g., GaAs) efficiently emit light and are used in optoelectronics.

- Indirect bandgap materials (e.g., Si) are less efficient in light emission but widely used in microelectronics due to superior processing characteristics.

1.3 Charge Carriers: Electrons and Holes

When electrons are excited into the conduction band, they leave behind holes in the valence band. Both electrons and holes act as charge carriers, moving under an electric field to create current. Semiconductor physics involves studying carrier concentration, mobility, recombination, and generation, which are critical for designing high-performance devices.

2. Semiconductor Materials

While silicon dominates the semiconductor industry, other materials are crucial for specialized applications.

2.1 Silicon (Si)

Silicon is abundant, inexpensive, and possesses excellent thermal stability and well-understood electronic properties. The Si-SiO2 interface is ideal for MOSFET fabrication, making silicon the material of choice for most microprocessors and memory chips.

2.2 Compound Semiconductors

Compound semiconductors combine elements from groups III and V (e.g., GaAs, InP) or II and VI (e.g., CdTe). They offer superior electron mobility, direct bandgaps, and high-frequency performance, making them ideal for RF devices, optoelectronics, and power electronics.

2.3 Wide-Bandgap Semiconductors

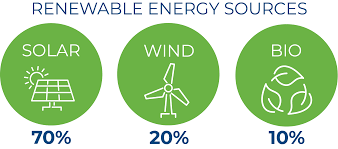

Materials like silicon carbide (SiC) and gallium nitride (GaN) have bandgaps significantly larger than silicon, enabling higher breakdown voltages, faster switching speeds, and operation at higher temperatures. They are increasingly used in electric vehicles, renewable energy systems, and high-power RF applications.

2.4 Emerging Materials

Research continues on two-dimensional materials like graphene and transition metal dichalcogenides (TMDs). These materials offer extraordinary electron mobility and unique optical properties, potentially enabling ultrafast, low-power transistors beyond silicon’s limits.

3. Transistor Technology: The Heart of Modern Chips

Transistors, which act as controllable switches or amplifiers, are the fundamental building blocks of semiconductor devices.

3.1 Bipolar Junction Transistors (BJT)

BJT devices rely on both electron and hole currents. While they were widely used in the past for analog applications, their higher power consumption and slower switching have made them less dominant in modern digital circuits.

3.2 Field-Effect Transistors (FET)

FETs, particularly MOSFETs (metal-oxide-semiconductor FETs), dominate contemporary electronics due to their high input impedance and scalability.

- Structure: Consists of a gate electrode, oxide insulator, and source/drain regions. Voltage applied to the gate controls the channel conductivity.

- Scaling Challenges: As devices shrink to sub-5 nm nodes, issues such as short-channel effects, leakage currents, and quantum tunneling become significant.

3.3 Advanced Transistor Architectures

- FinFETs: 3D transistors with vertical fins that improve gate control and reduce leakage.

- Gate-All-Around FETs (GAAFETs): Next-generation architecture for sub-3 nm nodes, where the gate surrounds the channel entirely, maximizing electrostatic control.

- Tunnel FETs and Beyond: Explored for ultra-low-power applications, exploiting quantum tunneling for switching.

4. Integrated Circuits and Chip Design

Modern chips integrate billions of transistors into complex integrated circuits (ICs), enabling microprocessors, GPUs, and memory modules.

4.1 Logic and Memory Circuits

- Logic ICs: Implement computational functions using gates (AND, OR, NOT) built from transistors.

- Memory ICs: Store information in volatile (DRAM, SRAM) or non-volatile (Flash, EEPROM) forms.

4.2 Design Automation

Electronic Design Automation (EDA) tools are essential for managing the complexity of billions of transistors. Tools include:

- Schematic Capture and Simulation: Functional verification of circuits.

- Layout Design: Physical design of ICs while meeting constraints like power, timing, and area.

- Verification and Testing: Ensures performance under manufacturing variations and environmental conditions.

4.3 Chip Packaging and Interconnects

Packaging impacts performance, thermal management, and reliability. Advanced techniques include:

- System-in-Package (SiP): Integrates multiple ICs into a single package.

- 3D Stacking (Through-Silicon Vias, TSVs): Reduces latency and increases bandwidth.

- Chiplet Architectures: Enables modular, heterogeneous integration of specialized functional blocks.

5. Semiconductor Fabrication Process

Fabricating a semiconductor chip is one of the most complex manufacturing processes in existence. A single 300 mm wafer can contain hundreds of ICs, with nanometer-scale features etched onto the silicon.

5.1 Wafer Preparation

- Crystal Growth: High-purity silicon crystals are grown using the Czochralski method.

- Wafer Slicing and Polishing: Crystals are sliced into thin wafers and polished to atomic-level flatness.

5.2 Lithography

Lithography defines the patterns of transistors and interconnects on the wafer. Modern techniques include:

- Deep Ultraviolet (DUV) Lithography: Traditional method using 193 nm light.

- Extreme Ultraviolet (EUV) Lithography: 13.5 nm wavelength enables sub-7 nm feature sizes.

5.3 Doping, Deposition, and Etching

- Ion Implantation and Diffusion: Introduce dopants into silicon to create p-n junctions.

- Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD): Deposit thin films of metals or insulators.

- Etching (Wet and Dry): Removes material selectively to define structures.

5.4 Chemical-Mechanical Planarization (CMP)

CMP ensures a flat surface for subsequent layers, critical for multilayer interconnects in advanced nodes.

5.5 Testing and Packaging

After fabrication, chips undergo electrical testing, yield analysis, and packaging before being shipped to customers.

6. Challenges in Modern Semiconductor Engineering

6.1 Scaling Limits

Moore’s Law, predicting transistor density doubling every 18–24 months, faces physical and economic limits. Sub-3 nm nodes confront quantum tunneling, variability, and extreme lithography challenges.

6.2 Power and Thermal Management

As transistor density increases, managing heat dissipation becomes critical. Advanced cooling solutions, low-power architectures, and energy-efficient materials are crucial.

6.3 Material and Process Innovation

New materials (high-k dielectrics, 2D materials) and process techniques (atomic-layer deposition, EUV) are required to maintain performance improvements.

7. Conclusion

Semiconductor technology represents one of humanity’s most extraordinary achievements in applied science and engineering. It combines fundamental physics, innovative materials, and sophisticated manufacturing processes to create devices that power modern life. From the atomic-level manipulation of silicon atoms to the integration of billions of transistors into a single chip, the field continues to push the boundaries of what is possible.

Understanding the science and engineering behind semiconductors is essential not only for engineers and scientists but also for anyone interested in the technological foundation of our digital world. As we approach the limits of traditional scaling, innovations in materials, architectures, and fabrication will define the next era of computing, communications, and beyond. Semiconductors will remain at the heart of these transformations, shaping the future of technology and society.